Our Products

Landscaping Materials

Bark, Mulch, & Shredded Options

Sand & Decomposed Granite (D.G.)

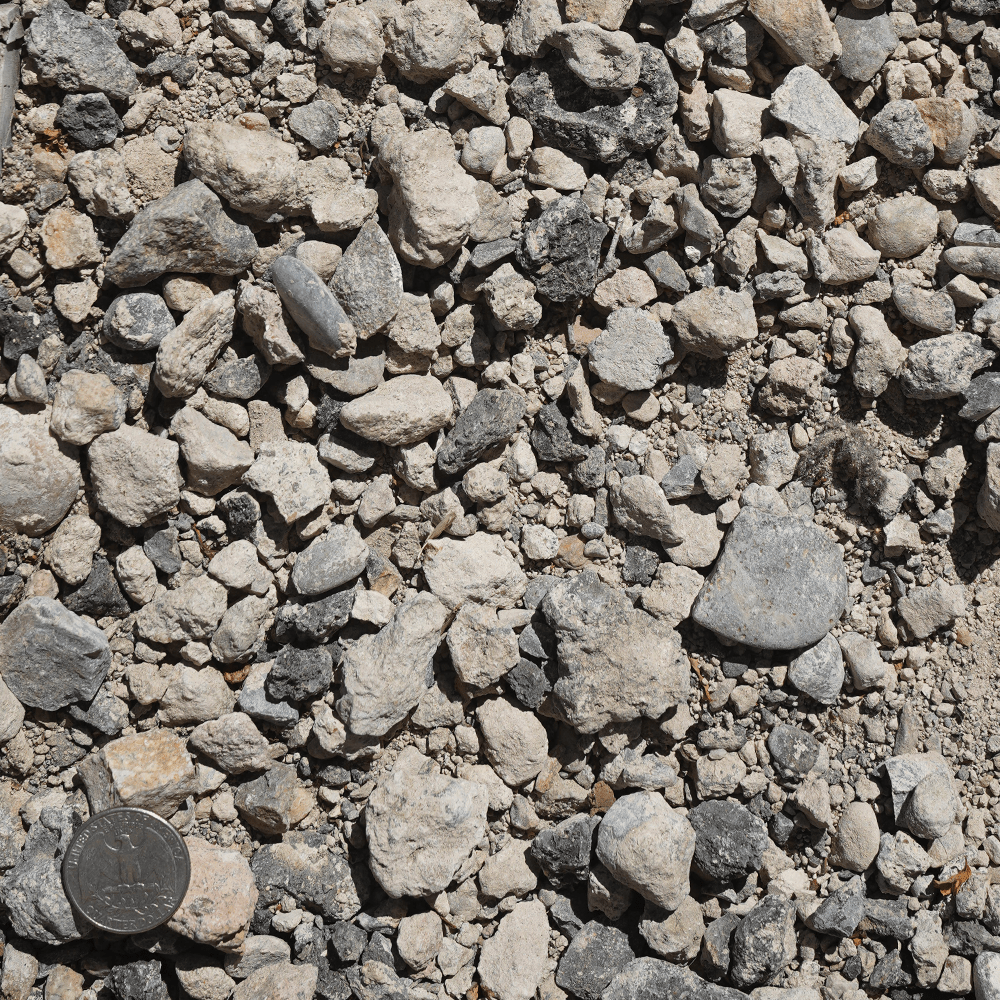

Gravel, Cobbles, & Rocks

A.B. Aggregate Base

Topsoil, Compost, Growing Soils, & Dirt

For Questions and Delivery Options Give Us A Call

Hanford’s Sweet Treat Concrete

Hanford Sand & Gravel, Inc. has quality concrete at competitive prices. Our concrete mixes typically surpass required strengths in 28 days. We have mixes with proven track records, thus giving our customers the confidence and satisfaction they have poured with the best.

A few of the products that we offer at Hanford Sand & Gravel are:

Custom Ready-mix Designs

Increte Concrete System

Hot & Cold Weather Concrete

Fiber for Ready-mix Designs

Euclid Ad Mixtures

Concrete Blocks

Landscaping Materials (Bulk or Bagged)

Common Ready-Mix Types

- Footing Mixes, Flatwork, and slab mixes

- Sacramento County Approved mixes

- Architectural, Stamped, colored, exposed, or plain concrete

- Lightweight rock mix

- Masonry Grout

- 3/8″ Pea Gravel mixes

- Black and White / Salt & Pepper Mixes

- Sand Slurry mixes

- 50/50 Aggregate Mixes

Euclid Admixtures

Euclid Chemical offers concrete and masonry admixtures, curing and sealing compounds, concrete repair mortars and toppings, adhesives, architectural and industrial coatings, dry shake floor hardeners, grouts, joint fillers, sealants, liquid densifiers, and water repellent sealers.

Solomon Color System Color Select

Colored concrete can be used to create a striking effect around your home or property while increasing your property’s value.

Color concrete can be stamped to look like brick, wood, tile, or stone at a much lower cost while providing greater longevity. You can combine subtle shades of colors, textures, and stamped patterns. You can also use multiple colors side by side, score joints, and saw cut patterns to visually break up large areas such as driveways, walkways, patios, and pool decks. Color will add appeal and ambiance to any property.

We can produce concrete in a wide range of colors: from various shades of gray and warm earth tones to vivid colors that range from warm to deep and dark to almost any color you can imagine. We can create hundreds of standard or custom color blends while maintaining a consistent color from batch to batch. Our computer-controlled system greatly minimizes human error. Your mix will be stored in our system, so if you need to match a color a year later we’ll have the exact specifications on file.

Fiber: A new generation in concrete reinforcement

Why should fiber reinforced concrete be used as temperature-shrinkage reinforcement instead of wire mesh? Plain and simple, the three-dimensional fiber reinforcement is proactive. Wire mesh is in a single plain of the concrete whereas the fibers are throughout the concrete working to enhance its long-term durability.

Applications for Fiber Reinforced Concrete:

Residential interior and exterior slabs-on-ground

- Driveways

- Patios

- Sidewalks

- Swimming Pools

- Swimming Pool Decks

- Basement Floors

- House Slabs

- Decorative Concrete

Benefits of Fiber Reinforced Concrete:

Why a 3-dimensional reinforcement works better than wire mesh

- Reduces plastic shrinkage cracking and plastic settlement

- Modifies micro-macro cracking of the hardened concrete

- Eliminates need for wire mesh for secondary reinforcement

- Reduces permeability

- Increases impact resistance

- Increases surface abrasion resistance

- Increases fatigue strength

- All of the above adds up to less maintenance and longer life

Choosing fiber reinforced concrete means you have selected current generation engineering technology. Fiber reinforcement starts working the minute the concrete is placed in the forms and works for the life of the concrete. Fiber reinforcement does not rust, rot or corrode. It is a lifetime companion with the concrete.

Available Aggregates (reach out for custom mix designs)

- 3/4″ Crushed Rock

- 3/8″ Pea Gravel – Three Colors Available

- Class II Aggregate Base

- Fill Sand

- Pea Gravel

- Round Rock

- 1 x 4 Con Mix

Other Available Supplies (please call for availability)

- 3/8″ x 3″ Expansion

- 3/8″ x 2″ Expansion

- Med Cure

- Water Base Cure

- Anchor Bolts 1/2″ x 10″ (100)

- Anchor Bolts 5/8″ x 10″ (100)

- 5 gal of Surface Retarder

- #1 Mil Plastic Roll 9′ x 400′

- #6 Mil Plastic Roll 20″ x 100′

- Concrete gloves

- Concrete Blocks

Artificial Grass And Synthetic Turf Products

Hanford Sand and Gravel sells a variety of hi-tech quality artificial grasses and synthetic turfs perfect for your project.

Our Concrete Blocks

Interlocking Concrete Blocks: Betonblock